Process Optimization

AUTOMATED MANUFACTURING EQUIPMENT

We design and deploy robust networking infrastructures tailored for manufacturing environments:

Networking Principles

Inspired by lean manufacturing:

-

Minimal and modular configuration—avoiding over-engineering.

-

Emphasis on diagnostics and transparency, making networks easy to monitor and maintain.

-

Standardized cable layouts and labeling, reducing setup and troubleshooting time.

Networking Solutions

Discover our innovative networking solutions designed to optimize your business operations and enhance connectivity.

Cybersecurity and Future-Proofing

-

VLANs, firewalls, and access control policies protect plant floor assets from threats.

-

Scalable infrastructure supporting IIoT and Industry 4.0 transitions.

-

Use of secure remote access solutions for diagnostics and updates.

Industrial-Grade Network Design

We design and deploy robust networking infrastructures tailored for manufacturing environments:

-

Use of industrial Ethernet (e.g., EtherNet/IP, Profinet, Modbus TCP) for deterministic, real-time communication between PLCs, HMIs, and SCADA systems.

-

Segmented architectures to isolate control systems from enterprise networks, enhancing reliability and security.

-

Redundant topologies (e.g., ring, star with failover) to ensure uptime in mission-critical systems

Integration with Automation Platforms

Networking isn’t siloed—it’s deeply integrated into the control architecture:

-

Seamless communication between PLCs, drives, sensors, and MES systems.

-

Use of protocol converters and managed switches to bridge different automation networks.

-

Optimized data flow for OEE tracking, downtime monitoring, and predictive maintenance analytics.

PLC Programming

Our engineers are proficient in a wide range of platforms including Allen-Bradley, Siemens, Omron, and more—ensuring flexible integration with existing systems.

Tailored Control Systems

We develop custom PLC programs designed to meet the exact specifications of your automated manufacturing processes, maximizing uptime and efficiency

Lean Programming

We follow structured, modular, and standardized programming methods rooted in lean manufacturing philosophies to reduce cycle time and simplify future updates.

Scalable Solutions

Whether you're automating a single machine or a full production line, our PLC programs are built for long-term scalability and reliability.

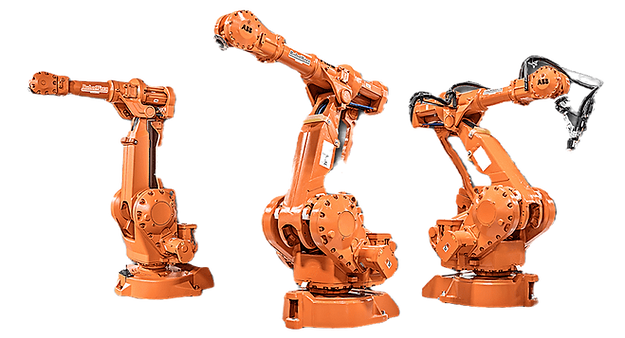

Robotic Programming

Our team programs across leading robot brands such as FANUC, ABB, Yaskawa Motoman, KUKA, and UR, working in collaboration with preferred integrators, ensuring compatibility with your preferred hardware

Seamless Integration

We sync robots with PLCs, vision systems, conveyors, and safety devices for smooth, coordinated automation.

Quick Deployment & Support

Fast turnaround on programming, commissioning, and troubleshooting to keep your project on track.

Cross-Platform Expertise

Skilled in FANUC, ABB, KUKA, Yaskawa, and more—new installs or legacy systems, we’ve got it covered.

Vision Integration

We design and implement advanced vision systems that bring intelligence and precision to your automated processes. From part inspection and orientation to pass/fail validation and robotic guidance, our solutions improve quality control, reduce manual intervention, and enhance overall production efficiency

Precision Part Detection

Reliable vision-guided systems for locating, inspecting, and verifying parts with high accuracy.

Smart Decision-Making

Integrate cameras and sensors to trigger real-time decisions—pass/fail checks, part sorting, and more.

Custom Solutions, Any Platform

Experience with Cognex, Keyence, Teledyne and more—tailored setups for your parts, lighting, and application.

Panel Building

we design and build industrial control panels that meet the highest safety and quality standards. Our panels are built for reliability, clean layout, and ease of maintenance—whether it's a standalone unit or part of a larger automation system.

UL508A Certified

Built to meet UL safety standards and comply with local and national electrical codes.

Clean, Serviceable Layouts

Every panel is professionally wired, labeled, and documented for long-term serviceability.

Fast Turnaround

Efficient build processes and component sourcing to keep your project on schedule.